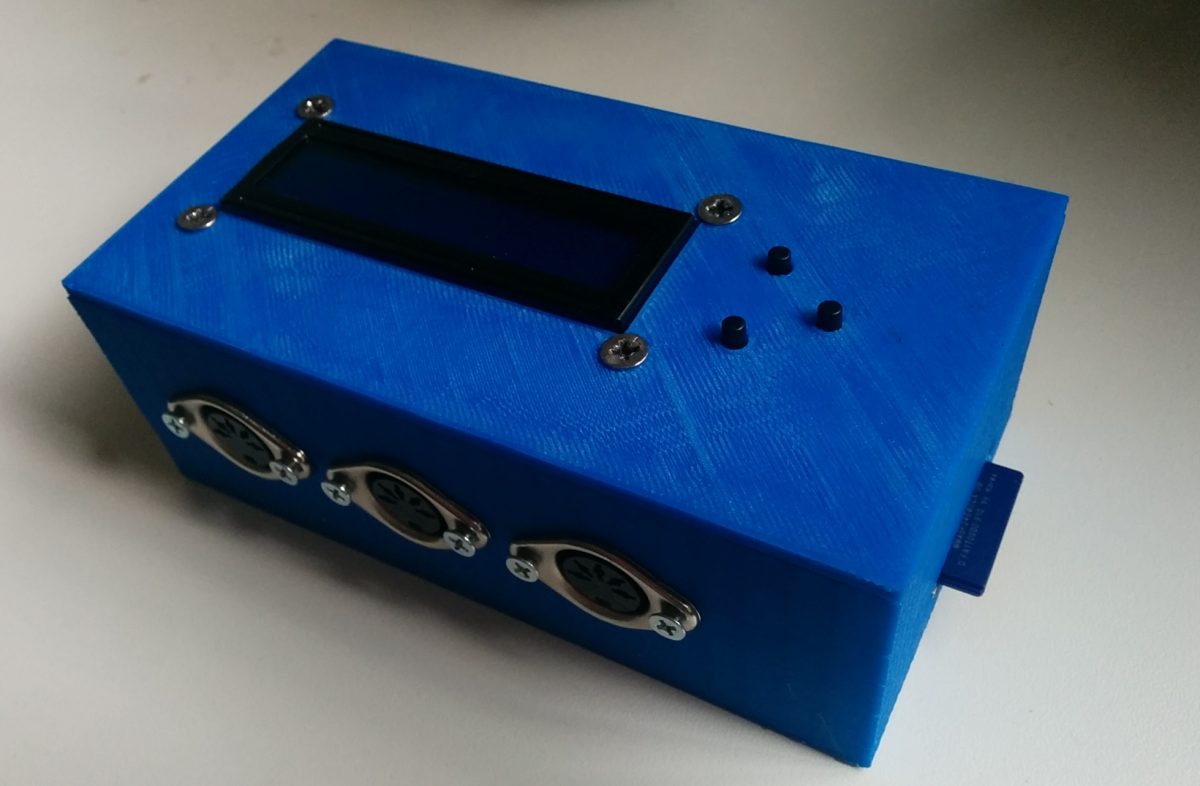

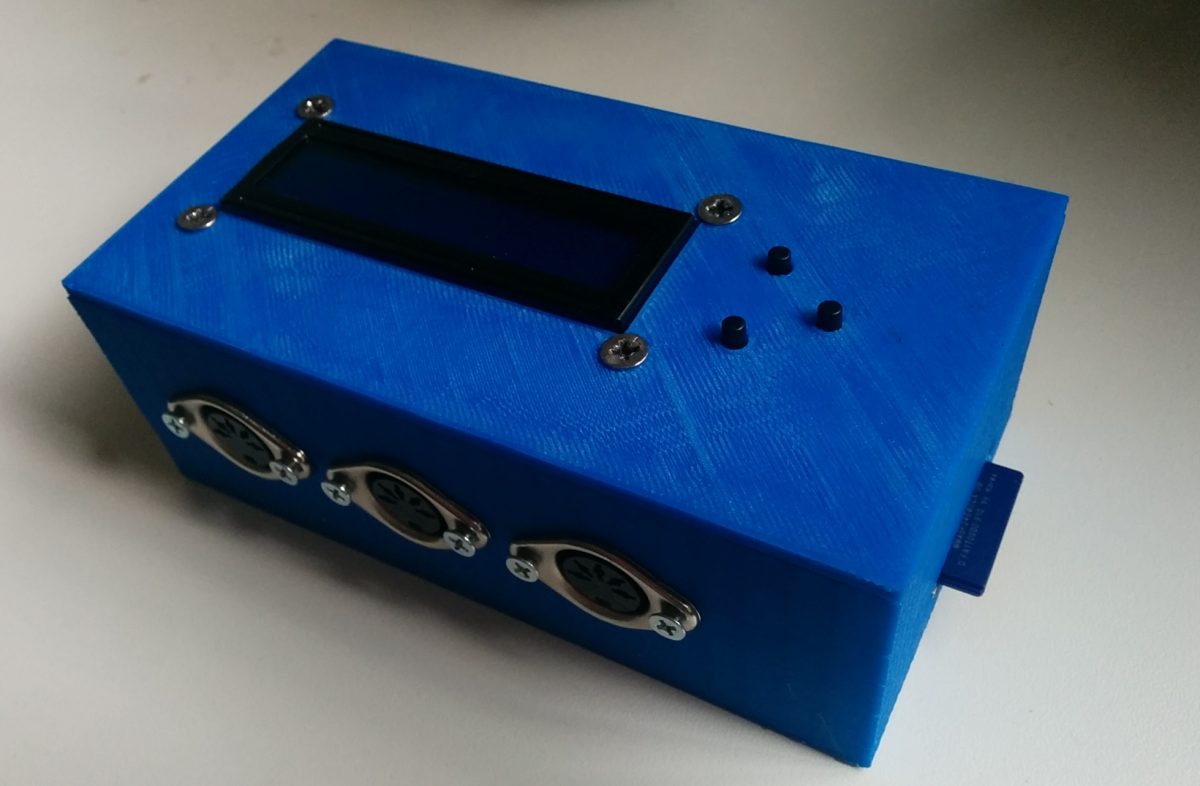

This will be a quick post about the design and 3D printing of a custom enclosure for a temperature logger (see full writeup here) –

Continue reading

The Deer… They are coming!

This will be a quick post about the design and 3D printing of a custom enclosure for a temperature logger (see full writeup here) –

Continue readingSo I’ve been going through a nostalgia period with my brewing, and this week it was time to make another go of my Sichuan Saison.

Continue reading

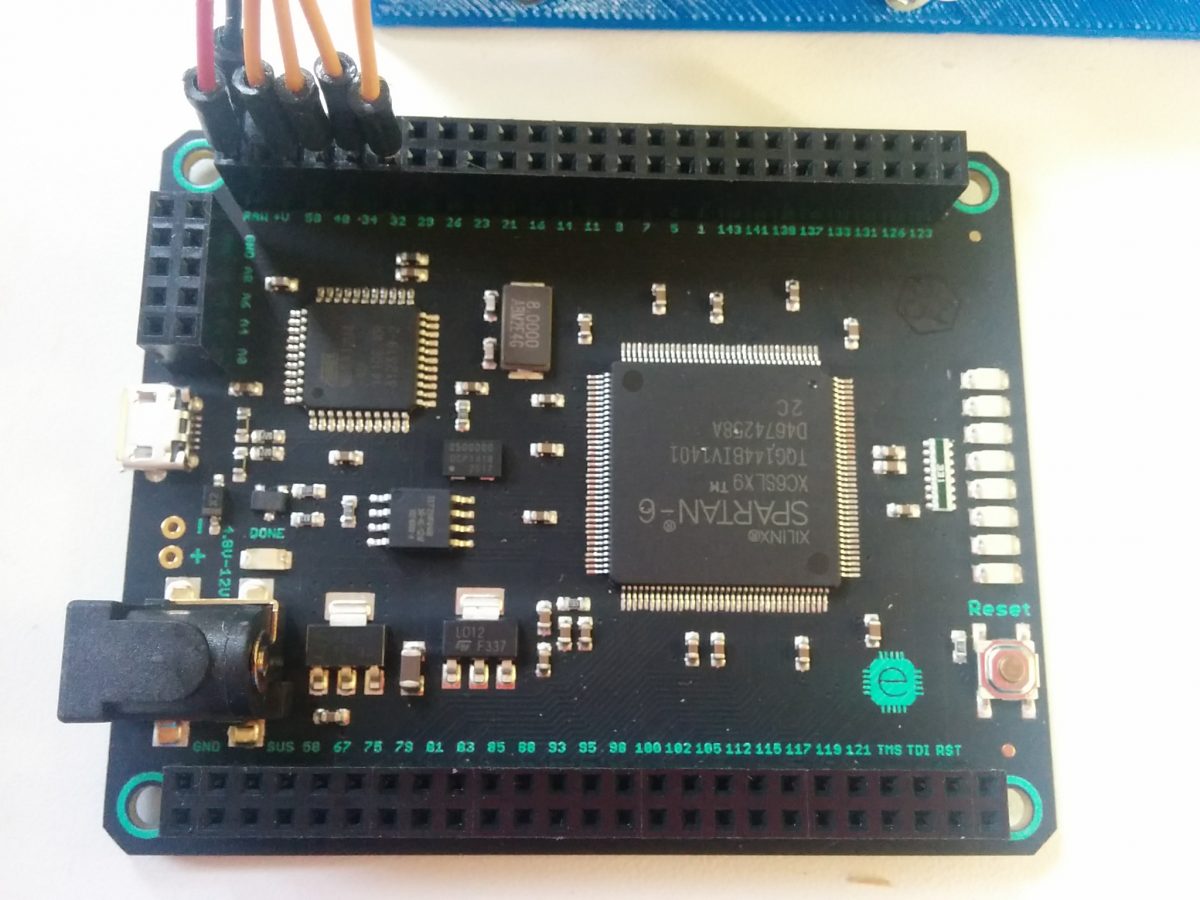

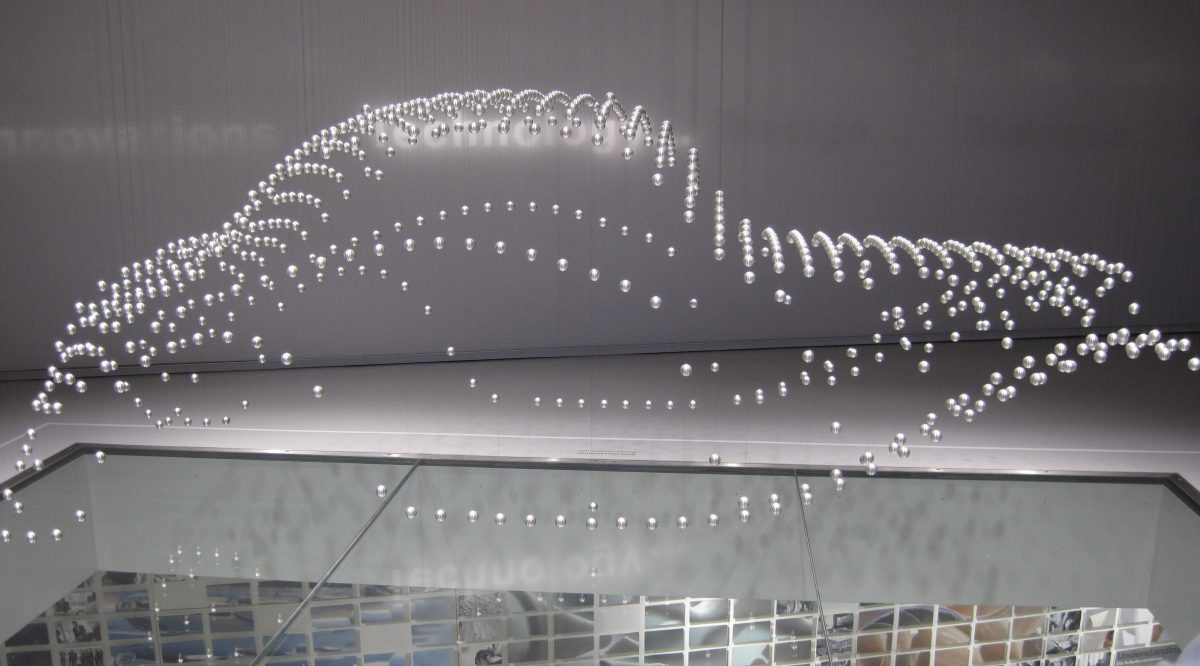

This post is part of my series on building a kinetic sculpture with the Mojo FPGA development board. (Part1 Part2) My Mojo development board finally turned

Continue readingA few months ago, I found myself with some old light malt extract, about 200g worth, and some sour yeast I had been gradually building

Continue reading

After returning from a trip to the maker faire in San Francisco last year I felt like I needed to get involved and buy myself

Continue readingHaving had a few weeks in the bucket to ferment, my dearly beloved hard as fuck IPA was ready for a few more weeks without

Continue reading

This post is part of my series on building a kinetic sculpture with the Mojo FPGA development board. (Part1 Part2) Back at uni I did

Continue reading

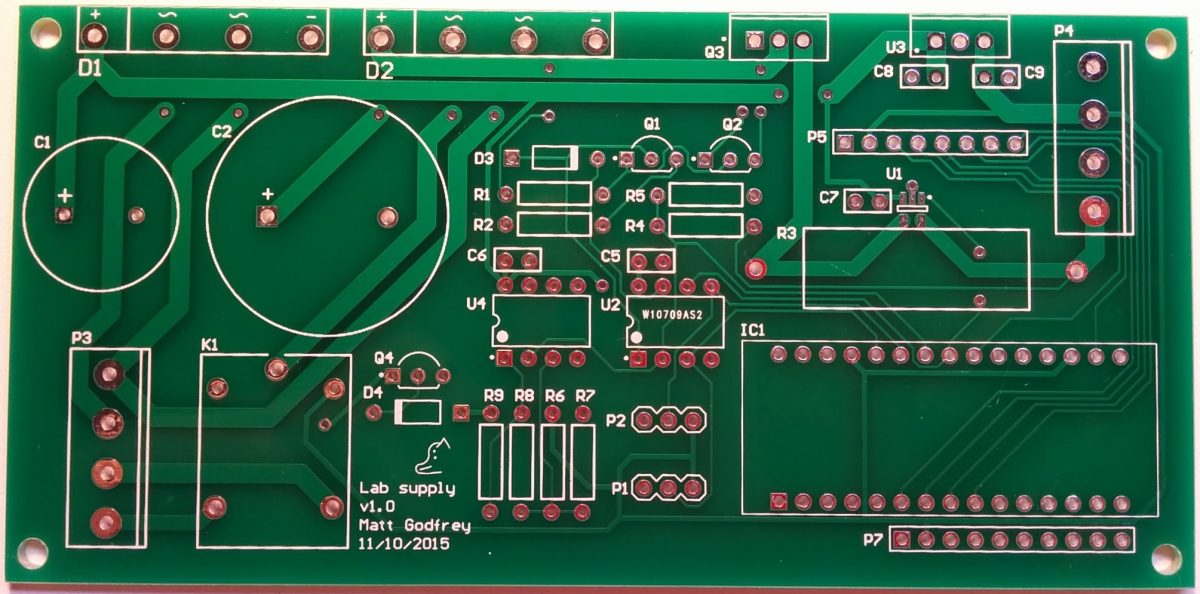

This is the first post on my power supply build. Also see part II and the Circuitmaker project page. An adjustable bench power supply has

Continue reading

This post is going to cover my first impressions of using Autodesk’s Fusion 360 CAD program from the point of view of someone who is

Continue reading

Cleaning out the garage I found/rediscovered some brass sheets which have been sitting there for quite a while, so my first thought was to attempt

Continue reading