This cabinet was designed for the living room to hold our modem/router and NAS on the lower shelf, covered by a door and with a

Continue reading

The Deer… They are coming!

This cabinet was designed for the living room to hold our modem/router and NAS on the lower shelf, covered by a door and with a

Continue reading

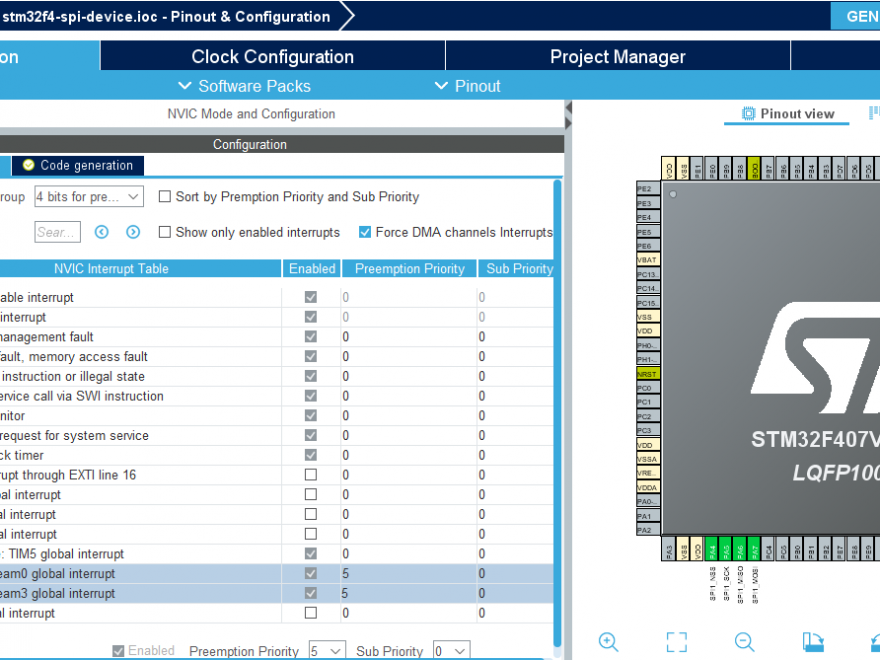

In this post I’ll go over my steps to get an STM32F4xx microcontroller running FreeRTOS as an SPI peripheral/device/slave using DMA so it can run

Continue reading

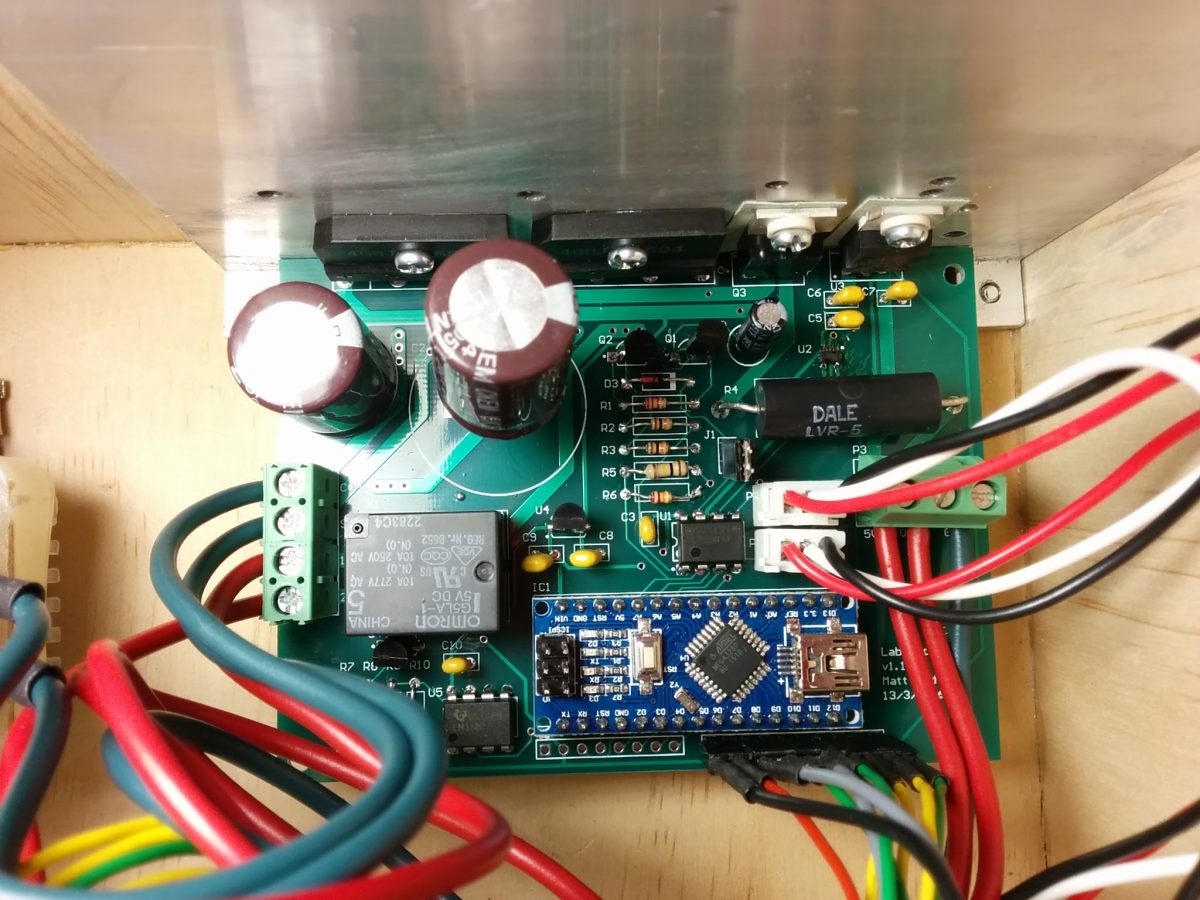

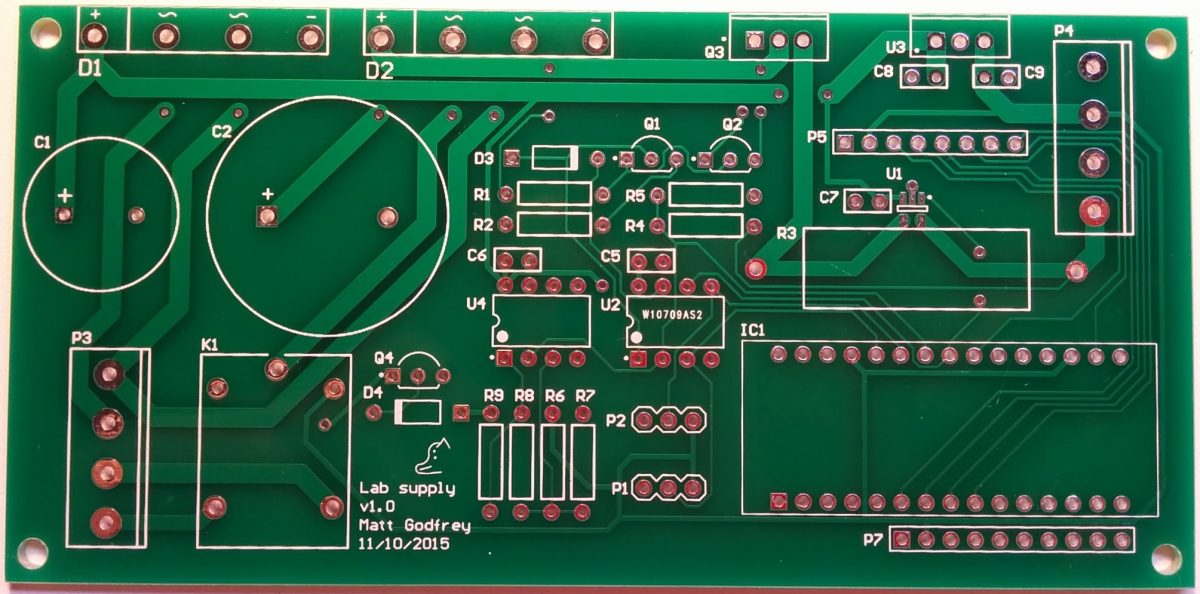

This is the second post on my power supply build – also see part I and the Circuitmaker project page. The aim of this project is to

Continue reading

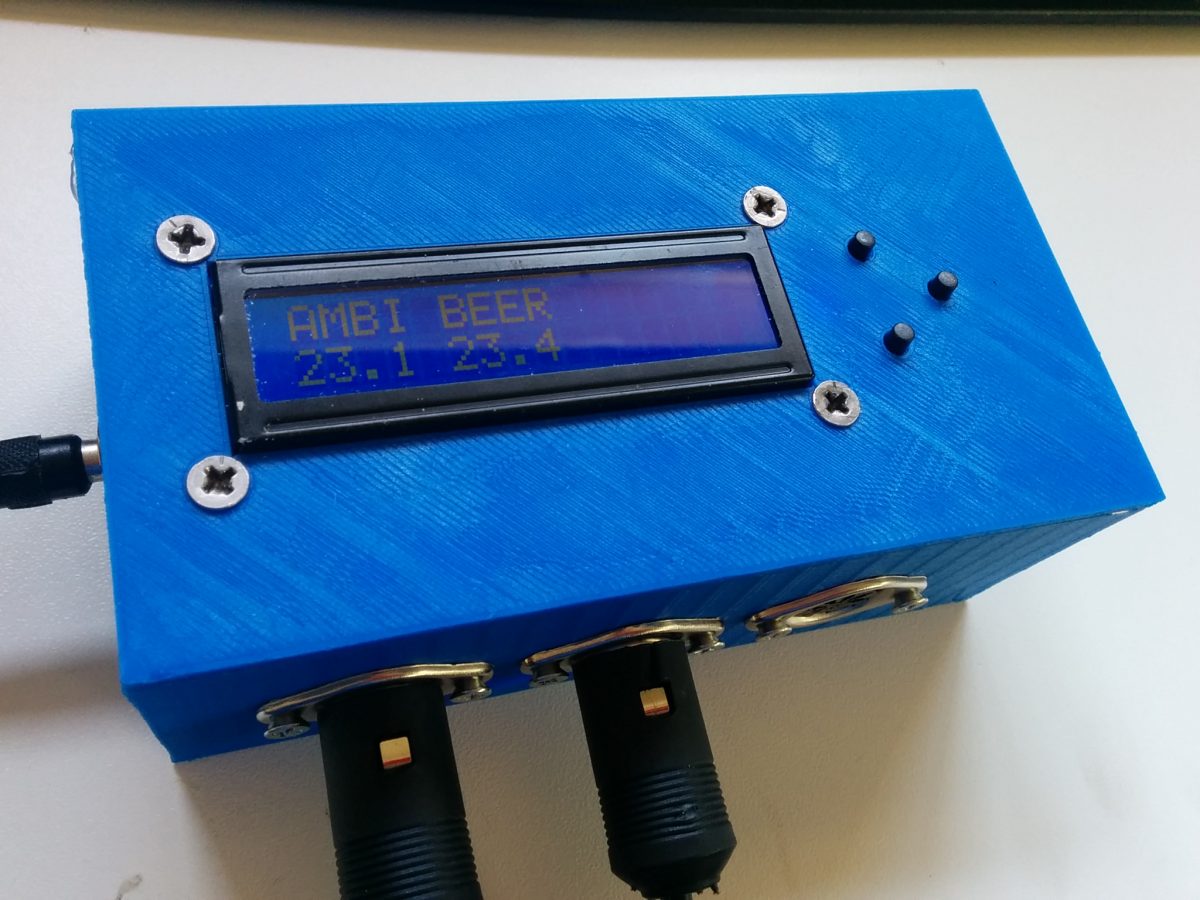

I have finally finished my temperature monitor and logging module, originally designed to monitor beer temperature as it is fermenting (beer, fridge and ambient temperatures).

Continue reading

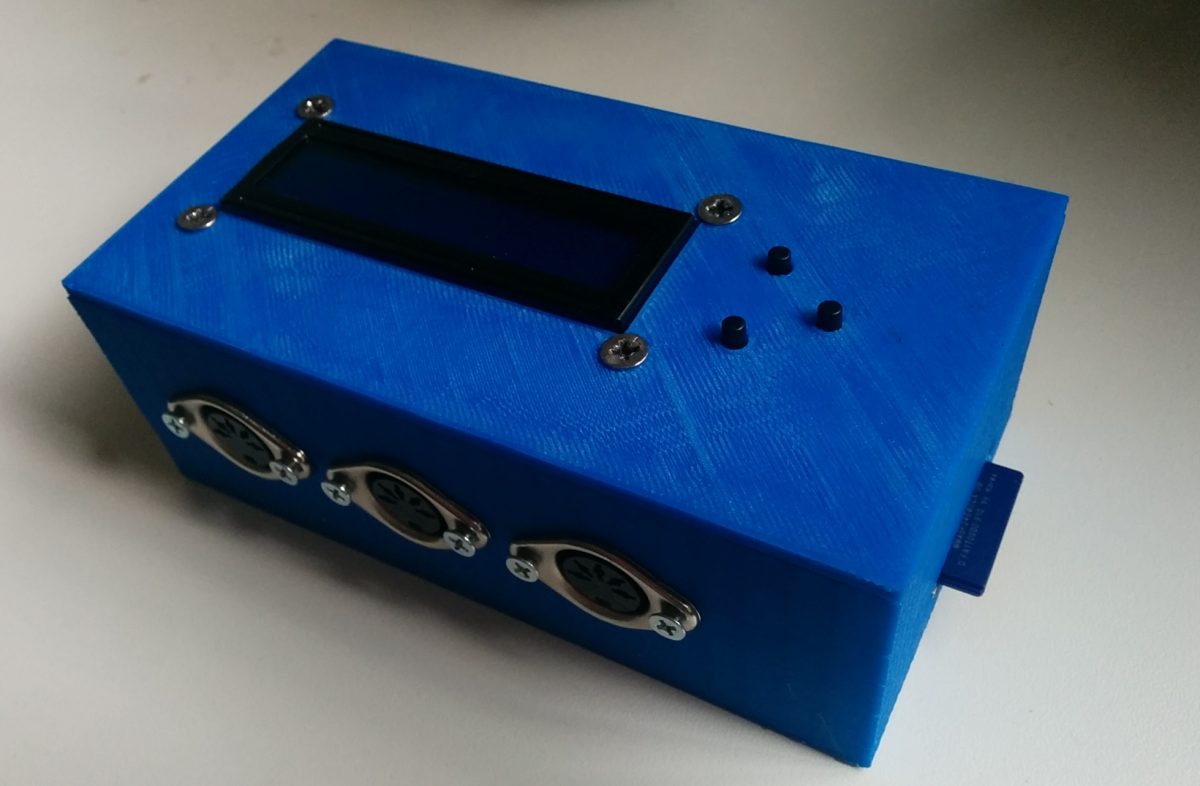

This will be a quick post about the design and 3D printing of a custom enclosure for a temperature logger (see full writeup here) –

Continue reading

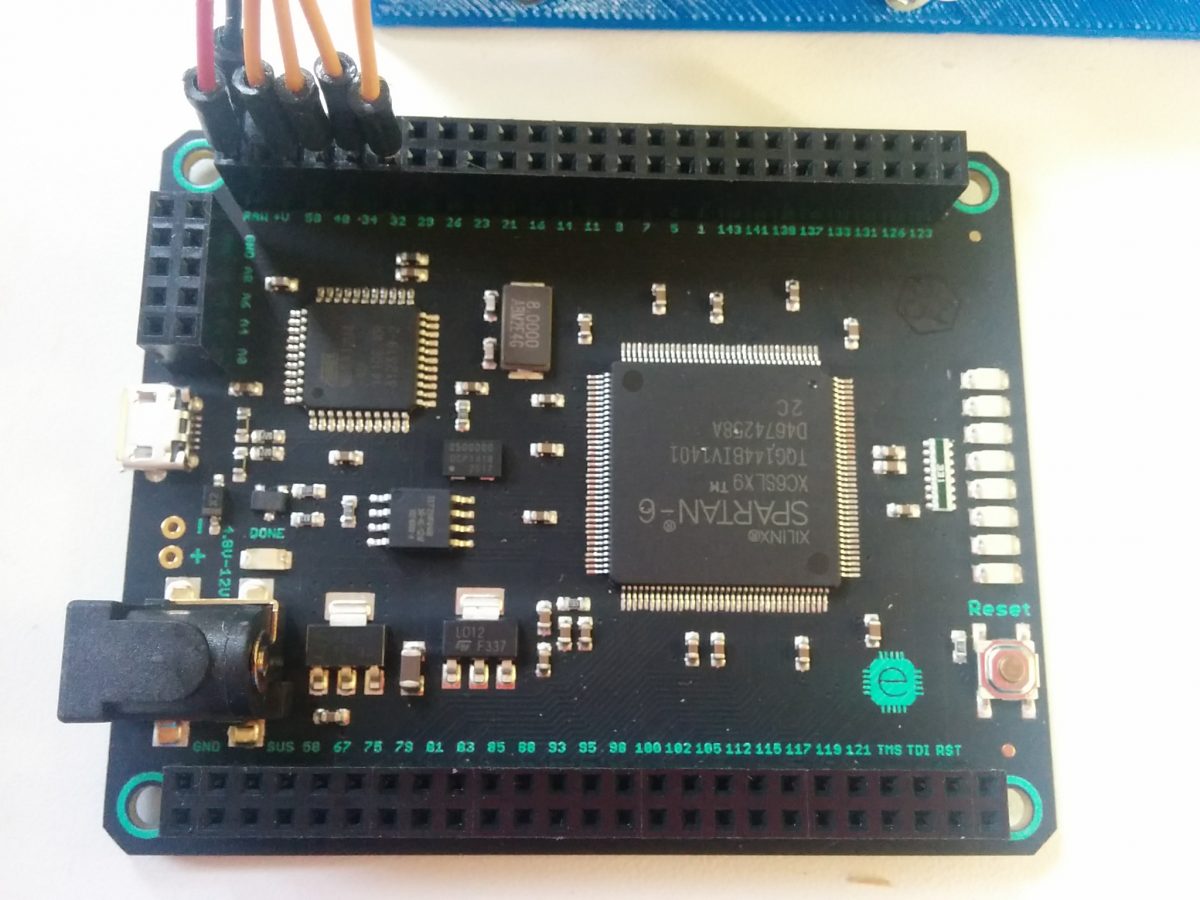

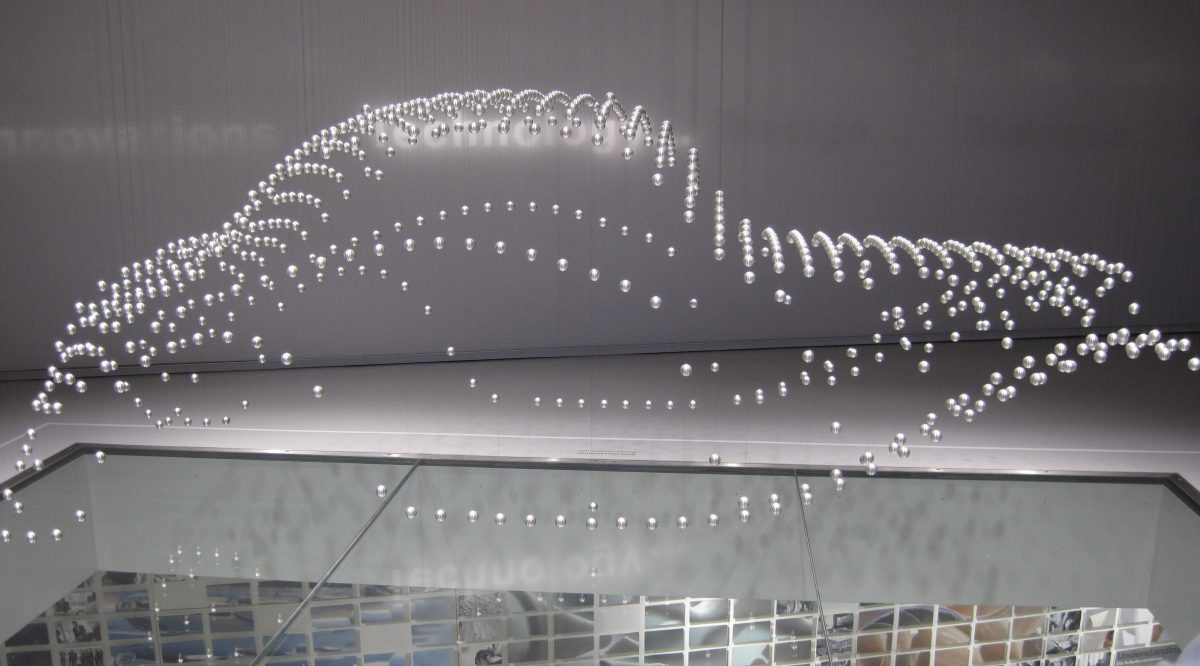

This post is part of my series on building a kinetic sculpture with the Mojo FPGA development board. (Part1 Part2) My Mojo development board finally turned

Continue reading

After returning from a trip to the maker faire in San Francisco last year I felt like I needed to get involved and buy myself

Continue reading

This post is part of my series on building a kinetic sculpture with the Mojo FPGA development board. (Part1 Part2) Back at uni I did

Continue reading

This is the first post on my power supply build. Also see part II and the Circuitmaker project page. An adjustable bench power supply has

Continue reading

This post is going to cover my first impressions of using Autodesk’s Fusion 360 CAD program from the point of view of someone who is

Continue reading